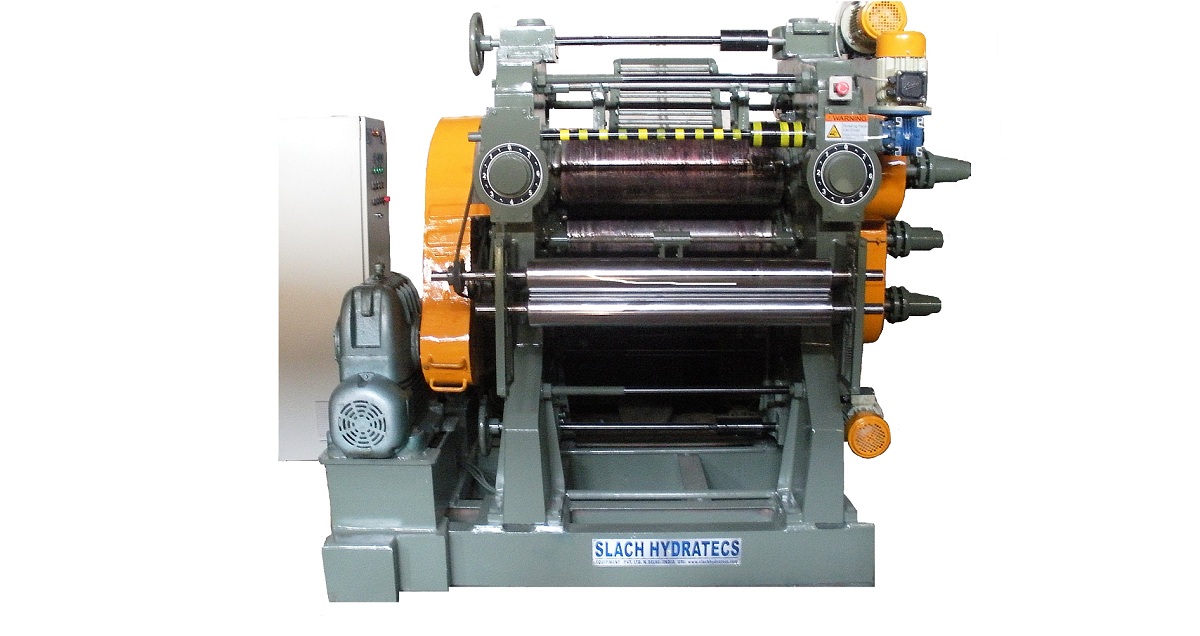

CALANDER (3/4/5 ROLL)

Calender mainly consist of roller, roller bearings rack, nip adjustment device, transmission system lubrication system, roll temperature adjustment device, security and control systems and other components.

- (1) The roller is hollow type, by steam heating or water cooling, the material is chilled allow cast iron, has high hardness and high abrasion resistance of the working surface after the grinding.

- (2) Transmission system is speed reducer and ratio grear driven by the motor so roller pairs relative to the direction of rotation. The motor is inverter motor the speed of roller is stepless variable which can timely reflect the speed of the roller on the control cabinet.

- (3) Nip adjustment device: lower rollers at both ends each have a set of controllable nip adjustment device and under the control of this device, the roller may be moving in the spout to achieve the purpose of adjusting distance. Each set of nip adjustment device by the reducer through a worm pay deceleration; the transmission screw rotate the nut which fixed on the rack thereby driven roller moving.

- (4) Roll temperature adjustment device: at one end of the machine equipped pipe valve with a thermostat device, open the valve, water or steam via the rotary joint into the roller, the roller is cooled or heated, through the heat exchange of the exhaust gas or vapor administered below the nozzle discharge. If more strict control of temperature, it can plus a thermostat heat exchanger.

- (5) Lubrication system: roller bearings is forced thin oil circulating lubrication, fuel tank filled with lubricating oil and equipped with a spiral cooling tube in order to reduce the oil temperature and ensure the good lubrication of the bearings. The oil pressure is generally adjusted in 0.1- 0.2MPa and adjust the pressure through the regulator, the lubrication system set of two filters, unscrew the top cover and take out the filter and clean with kerosene to maintain a smooth flow of clean oil line; ratio gear lubrication is also the oil pump to the oil circulation lubrication; reducer using thin oil nationality gear lubrication oil level should be maintained within the oil gauge scale shown; reducer of the nip adjustment device, when installed in the machine or repair after the first use, should be screwed open box cover at the top of the plug, inject a certain amount of lubricating oil; worm gear box grease plug injected from a tank shell, remove the scale on the top cover, from screw end oil cup inject grease for lubrication screw.